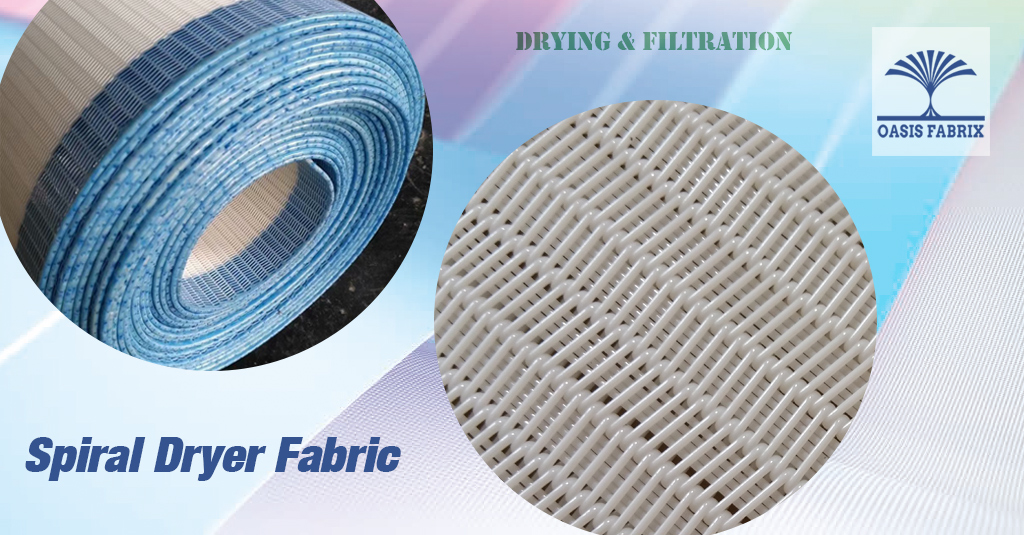

Polyester Spiral Dryer Fabrics with glued edges, available in various colors.

Polyester Spiral Dryer Fabrics with glued edges, available in various colors.

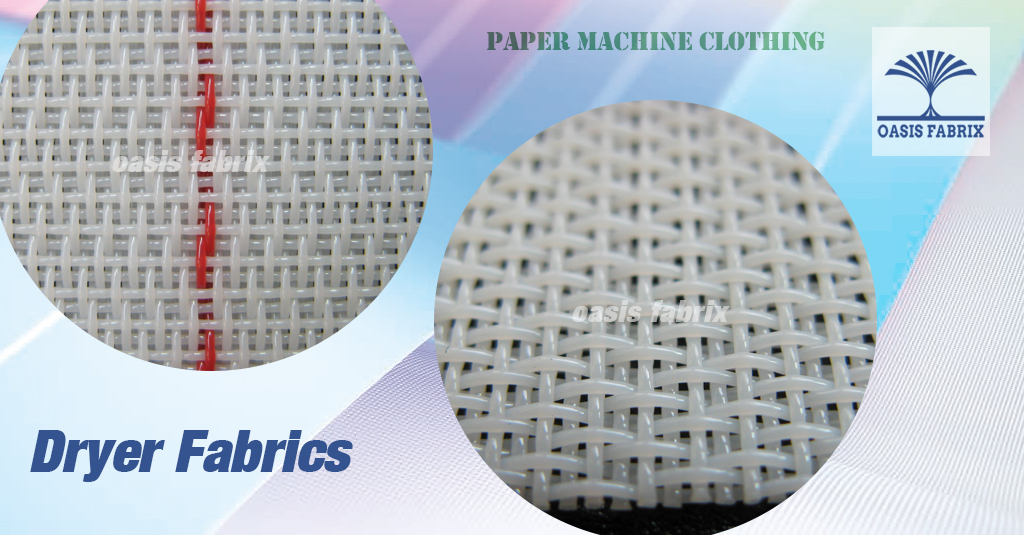

The seams matter much to dryer fabric performance, our dryer fabrics are jointed of spiral seams, inline loop seams (warp yarns woven back).

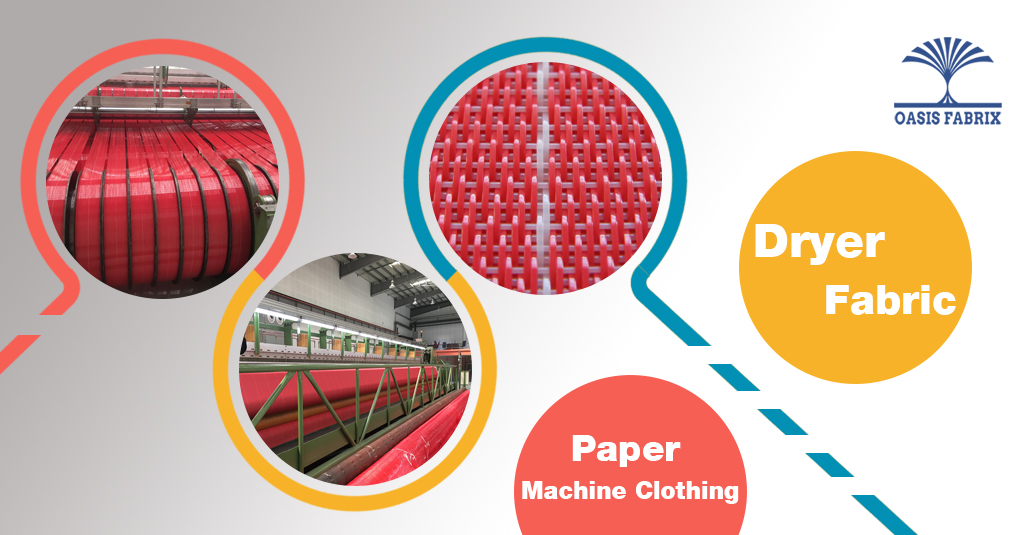

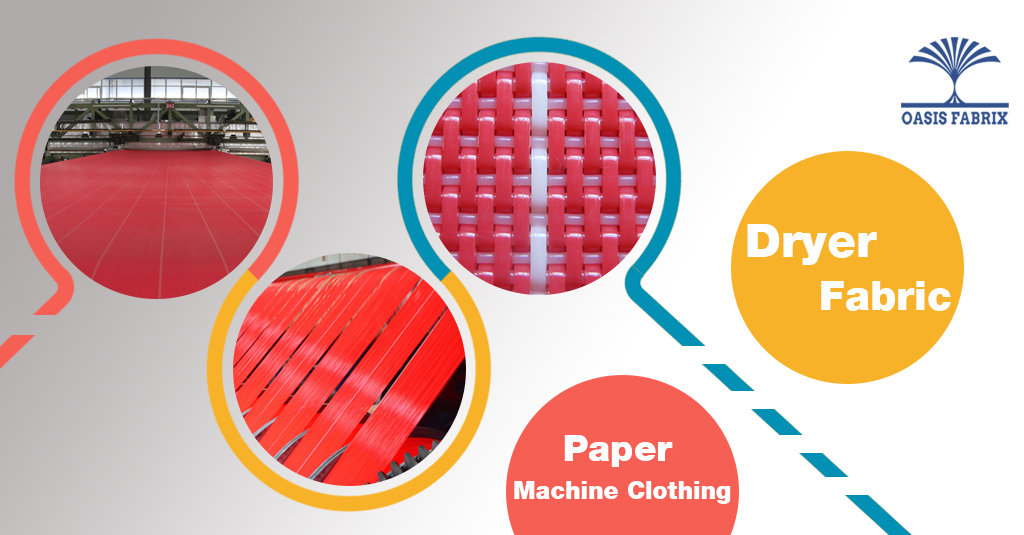

Dryer fabrics, dryer screens for paper making, paper machine clothing.

Flat yarn dryer fabrics, dryer screens for paper making, paper machine clothing.

Spiral dryer fabrics, spiral mesh belts available in white, black colors…

Polyester spiral dryer fabric with 1 to 5 filler yarns and glued edges for drying and filtration.

Polyester Dryer Fabrics, Dryer Screens for Paper making.

Polyester spiral dryer fabrics, Spiral dryer screen, Spiral filter cloth and mesh belt.